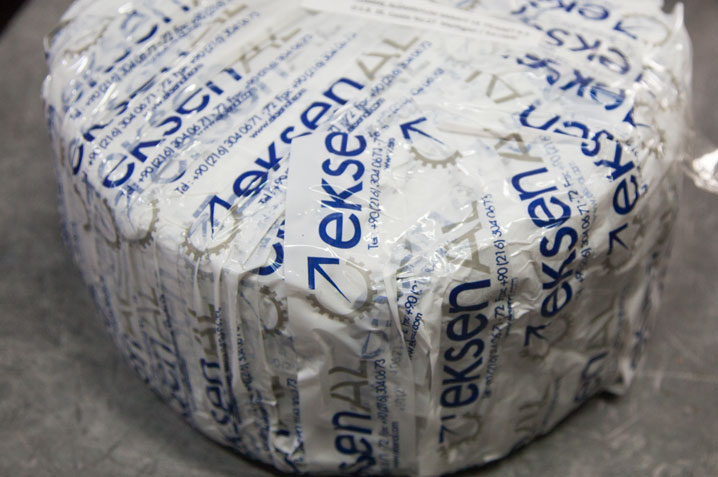

eksenAL

trust with eksenAL

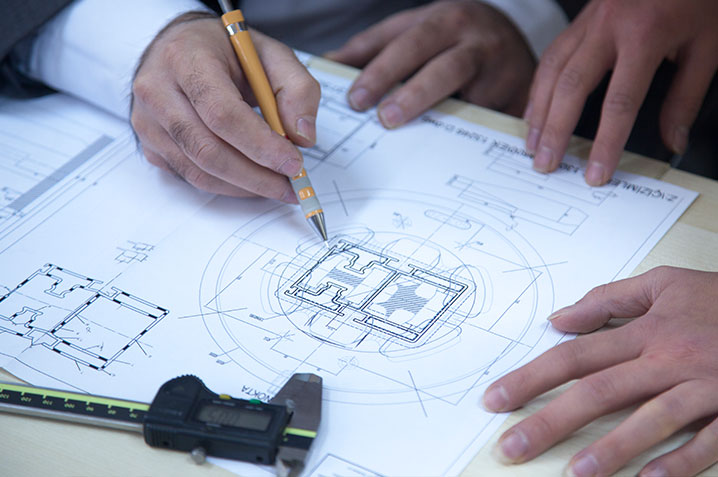

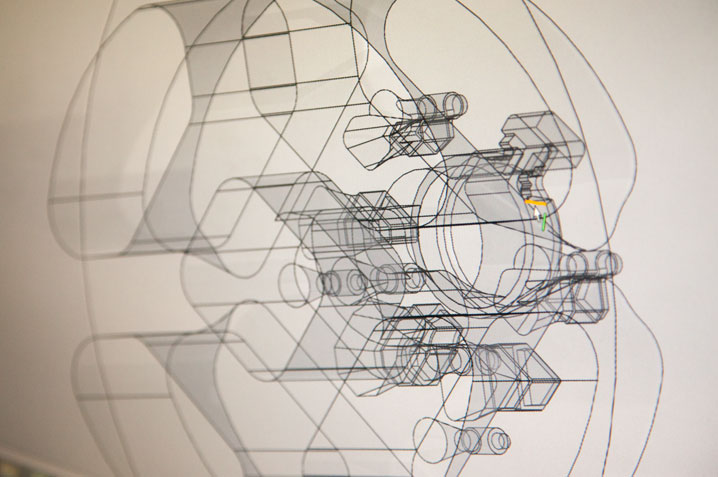

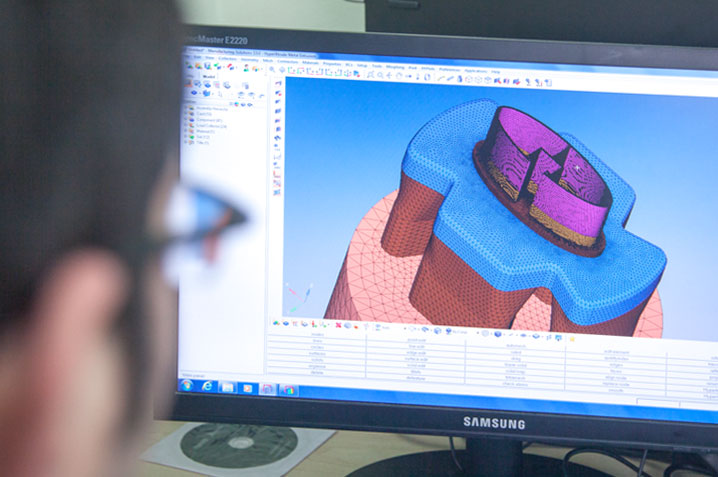

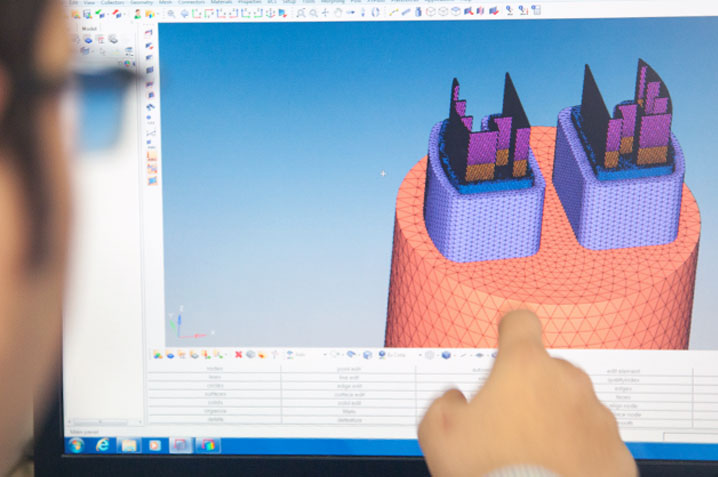

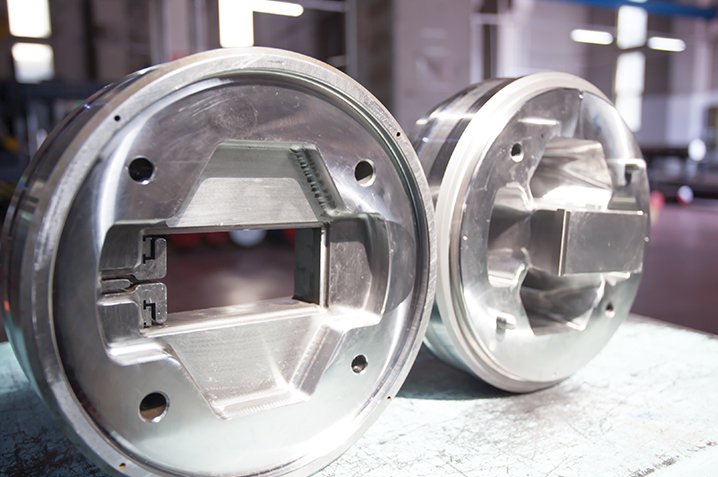

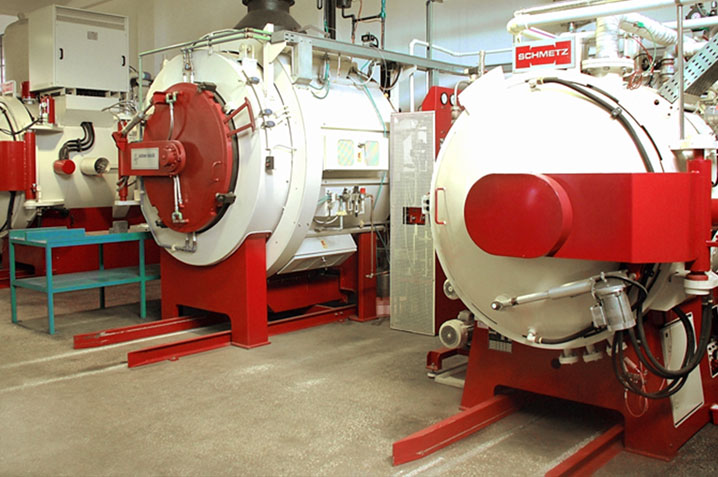

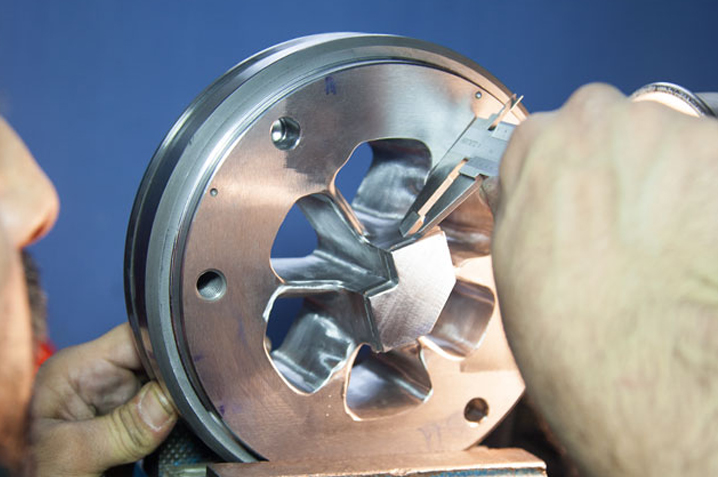

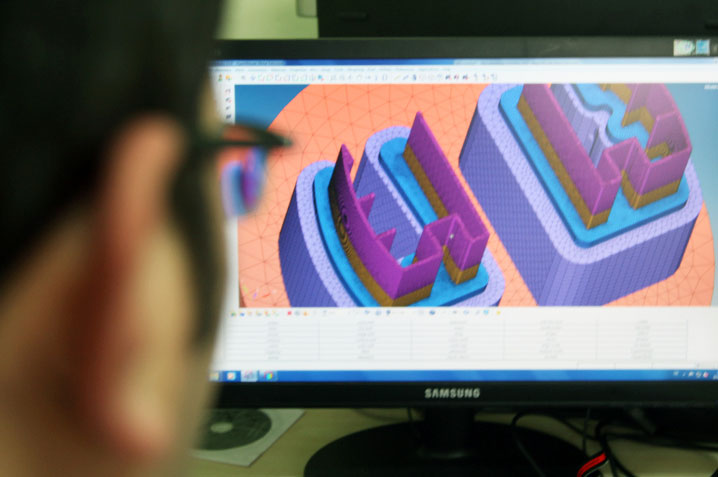

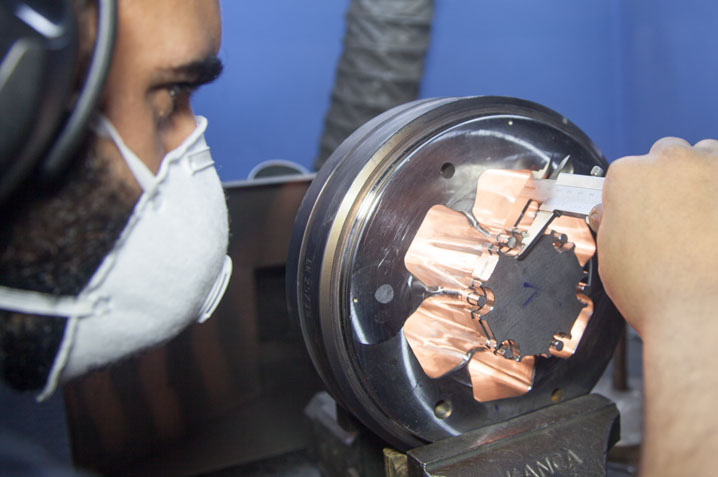

The motto, which eksenAL offers, establishing production criteria and trends with innovative institutional behavior in the sector of Aluminum Extrusion Profile die is the quality without compromise....

T: +90 262 502 9111 - 2 - 3

F: +90 262 502 9115

info@eksenal.com

T: +90 262 502 9111 - 2 - 3

F: +90 262 502 9115

info@eksenal.com

İstanbul Mermerciler Küçük San. Sit. 23.Sk NO:12 Köseler Mh. DİLOVASI / KOCAELİ

eksenAL -Alüminyum Ekstrüzyon Kalıp Teknolojileri' nin üretim sürecini ve firma profilini anlatan video